Low-Volume Metal Brackets

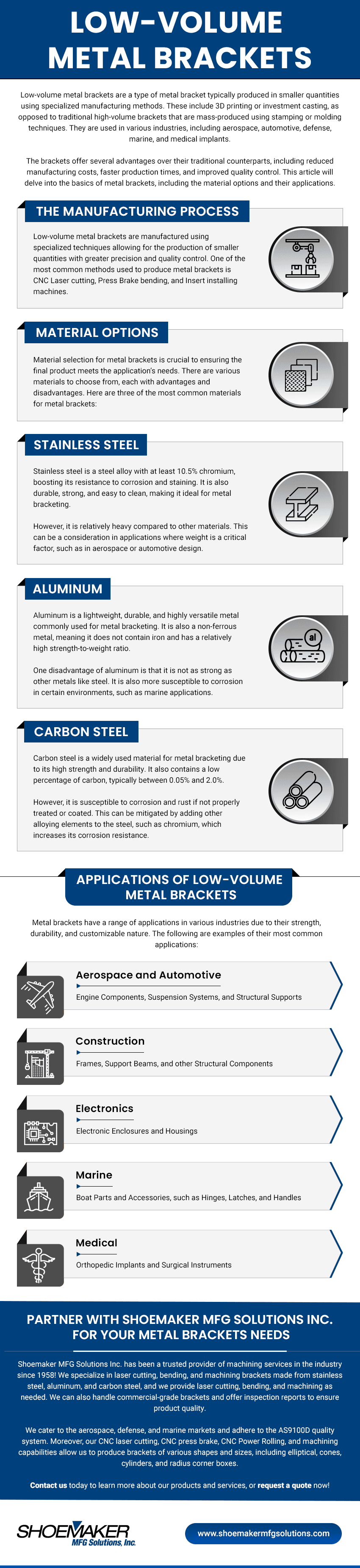

Leave a CommentLow-volume metal brackets are a type of metal bracket typically produced in smaller quantities using specialized manufacturing methods. These include 3D printing or investment casting, as opposed to traditional high-volume brackets that are mass-produced using stamping or molding techniques. They are used in various industries, including aerospace, automotive, defense, marine, and medical implants.

The brackets offer several advantages over their traditional counterparts, including reduced manufacturing costs, faster production times, and improved quality control. This article will delve into the basics of metal brackets, including the material options and their applications.

The Manufacturing Process

Low-volume metal brackets are manufactured using specialized techniques allowing for the production of smaller quantities with greater precision and quality control. One of the most common methods used to produce metal brackets is CNC Laser cutting, Press Brake bending, and Insert installing machines.

Material Options

Material selection for metal brackets is crucial to ensuring the final product meets the application’s needs. There are various materials to choose from, each with advantages and disadvantages. Here are three of the most common materials for metal brackets:

Stainless Steel

Stainless steel is a steel alloy with at least 10.5% chromium, boosting its resistance to corrosion and staining. It is also durable, strong, and easy to clean, making it ideal for metal bracketing.

However, it is relatively heavy compared to other materials. This can be a consideration in applications where weight is a critical factor, such as in aerospace or automotive design.

Aluminum

Aluminum is a lightweight, durable, and highly versatile metal commonly used for metal bracketing. It is also a non-ferrous metal, meaning it does not contain iron and has a relatively high strength-to-weight ratio.

One disadvantage of aluminum is that it is not as strong as other metals like steel. It is also more susceptible to corrosion in certain environments, such as marine applications.

Carbon Steel

Carbon steel is a widely used material for metal bracketing due to its high strength and durability. It also contains a low percentage of carbon, typically between 0.05% and 2.0%.

However, it is susceptible to corrosion and rust if not properly treated or coated. This can be mitigated by adding other alloying elements to the steel, such as chromium, which increases its corrosion resistance.

Applications of Low-Volume Metal Brackets

Metal brackets have a range of applications in various industries due to their strength, durability, and customizable nature. The following are examples of their most common applications:

- Aerospace and automotive: engine components, suspension systems, and structural supports

- Construction: frames, support beams, and other structural components

- Electronics: electronic enclosures and housings

- Marine: boat parts and accessories, such as hinges, latches, and handles

- Medical: orthopedic implants and surgical instruments

Partner With Shoemaker MFG Solutions Inc. for Your Metal Brackets Needs

Shoemaker MFG Solutions Inc. has been a trusted provider of machining services in the industry since 1958! We specialize in laser cutting, bending, and machining brackets made from stainless steel, aluminum, and carbon steel, and we provide laser cutting, bending, and machining as needed. We can also handle commercial-grade brackets and offer inspection reports to ensure product quality.

We cater to the aerospace, defense, and marine markets and adhere to the AS9100D quality system. Moreover, our CNC laser cutting, CNC press brake, CNC Power Rolling, and machining capabilities allow us to produce brackets of various shapes and sizes, including elliptical, cones, cylinders, and radius corner boxes.

Contact us today to learn more about our products and services, or request a quote now!

Five-Axis Milling Machine

Leave a CommentShoemaker MFG Solutions Inc. has prioritized consistently delivering the latest cutting-edge technology as a leading provider of precision metal products and services. We focus on precision and innovation, which allows us to cater to various industries, such as aerospace, defense, marine and commercial.

We proudly announce our newest addition: the 2022 FANUC RoboDrill α-D21LiB5ADV. This machine represents the pinnacle of precision engineering, equipped with full five-axis milling capabilities. It is a versatile tool that can be used across various industries, making it an essential addition to any modern workshop.

How Does a Five-Axis Milling Machine Work?

A five-axis milling machine is a computer-controlled tool that simultaneously moves a workpiece in five directions. This ability to drive a workpiece in multiple directions makes it possible to create complex shapes and designs with unparalleled precision. In addition, the machine uses a series of cutting tools mounted on a rotating spindle to remove material from the workpiece.

The workpiece can be rotated and tilted in different directions to give the cutting tool access to multiple faces of the workpiece. The machine is controlled by a computer program that provides precise instructions to the motors and actuators. This allows it to make highly detailed cuts with high repeatability.

Shoemaker’s 2022 FANUC RoboDrill α-D21LiB5ADV

The FANUC RoboDrill is a state-of-the-art machining center that has earned its reputation as one of the most reliable machines in the industry. With a record of exceptional performance and precision, it is a popular choice for manufacturers worldwide.

Here are some of the features and characteristics of our new acquisition:

Speed and Efficiency

Its speed and efficiency are two key features that set the RoboDrill apart from other machining centers. Thanks to its advanced technology and high-performance cutting tools, the machine can complete milling, drilling, and tapping jobs quickly and accurately. Moreover, FANUC RoboDrill α-D21LiB5ADV boasts 10,000 RPM.

Reliability

In addition to its impressive performance capabilities, the RoboDrill is renowned for its reliability. Every aspect of the machine has been designed with durability and dependability, from the high-quality components to the advanced control systems. This commitment to reliability ensures that equipment can deliver consistent, accurate results over the long term.

User-Friendly Control Panel

The user-friendly control panel of the 2022 FANUC RoboDrill α-D21LiB5ADV is a standout feature that sets it apart from other machines in its class. The interface has been designed to provide operators with a simple and intuitive way to program and control the machine’s movements and cutting operations. The panel also includes helpful tools and features that simplify the machine’s programming.

Other Relevant Acquisitions

Shoemaker has made several key equipment acquisitions that have significantly enhanced our operations. These advanced tools deliver exceptional precision and efficiency, helping us meet the demands of even the most complex and challenging manufacturing projects.

Nikken Five-Axis Indexer

The Nikken Five-Axis Indexer is designed to enable precision measurement of complex and free-form surfaces. It is an advanced system combining a 3D touch probe with a motorized rotary table, enabling high-precision measurement from multiple angles and orientations.

Renishaw RMP400 Part Probe

The Renishaw RMP400 Part Probe is a versatile tool that can be applied in various processes such as milling, turning, and grinding operations. It is a non-contact probe that communicates with the machine control system through radio transmission, delivering speedy information on the part’s location and alignment. It can also achieve precise measurement of intricate part geometries with exceptional accuracy.

RTS Tool Probe With Axis

The RTS Tool Probe is used in CNC machining operations to measure cutting tools’ length, diameter, and offsets rapidly and accurately. By doing so, the machine can account for tool wear and maintain consistent quality in the production process. It can also be employed in vertical and horizontal machining centers and is adaptable to various CNC machines and software systems.

Choose Shoemaker MFG Solutions Inc. for High-Quality Machining and Fabrication Services

Shoemaker has been a trusted provider in the industry since 1958, offering a comprehensive suite of machining services tailored to meet your unique requirements! Our company is dedicated to providing outstanding service and dependability, as evidenced by our compliance with ITAR regulations and registration with AS9100D.

Contact us today to speak with our specialists, or request a quote now!