Machining and Welding

From our humble beginnings as a welding outfit in a single-bay garage in 1958 to a full-service metal fabrication company today, Shoemaker has proven to be an industry leader in metal fabrication. Specializing in welding, machining, and metal fabrication, we rely on skill, dependability, and integrity to drive the growth of our business. With our dedication to continuous improvement and delivery of exceptional products, we are able to custom-fit every project to our customers’ needs.

Machining and Welding Capabilities

Our specialists are known for their workmanship across the industries we serve. Our team produces superior quality products on time and at competitive prices. We can accommodate any size production run — from large-scale production runs to a one-off custom order, our team has the experience and skill to expertly produce your components to your exact specifications. Our capabilities include:

- Welding: To ensure the highest quality welds, all of our welders are either NAVSEA, AWS, or ASME certified, and every weld is inspected by a certified Level 2 weld inspector. Our technicians are skilled in MIG, TIG, and Stick welding processes and they can determine the most appropriate use of heat, filler materials, gas, and pressure for any given situation. We can assist you in reducing the time and costs associated with your project.

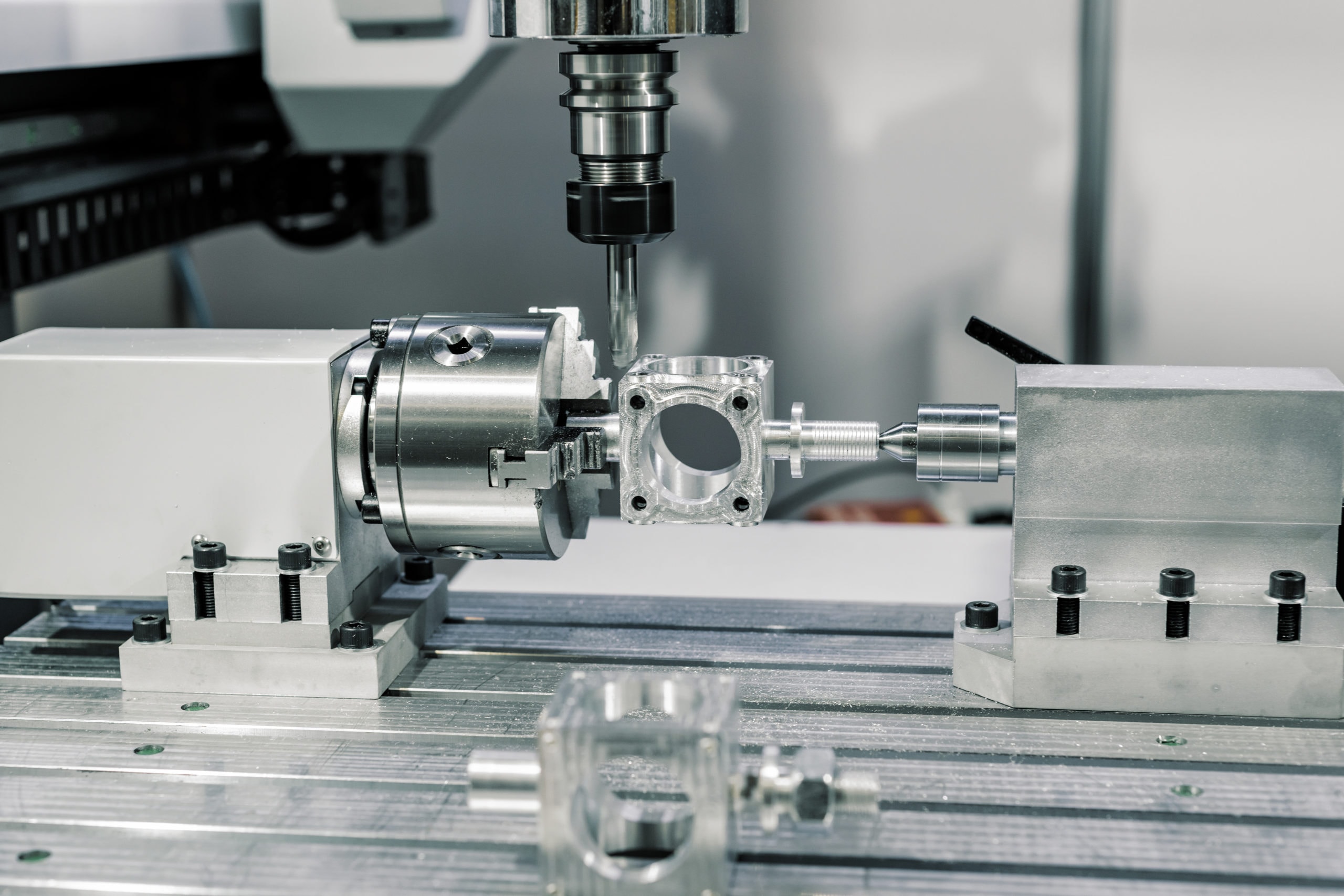

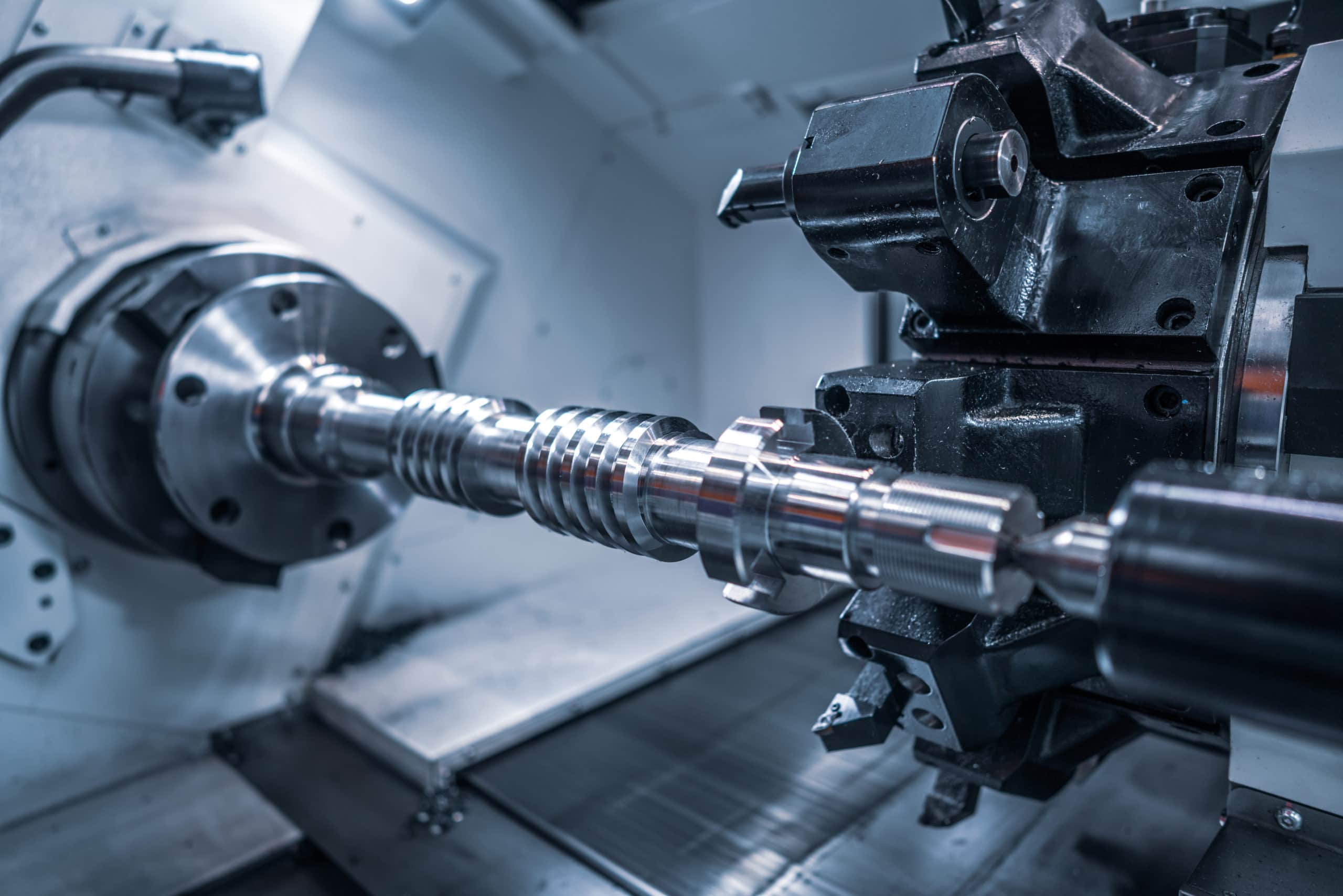

- Machining: Shoemaker employs state-of-the-art CNC technology and software to produce high-precision components for a wide range of industries. We house a variety of automated and manual machining equipment in our facility to accommodate prototyping needs and full-volume production runs. We use our multi-axis mills and turning centers, presses, hones, bands saws, and more to facilitate a range of machining processes, including CNC turning, 3D dynamic machining, knurling, threading, drilling, and more.

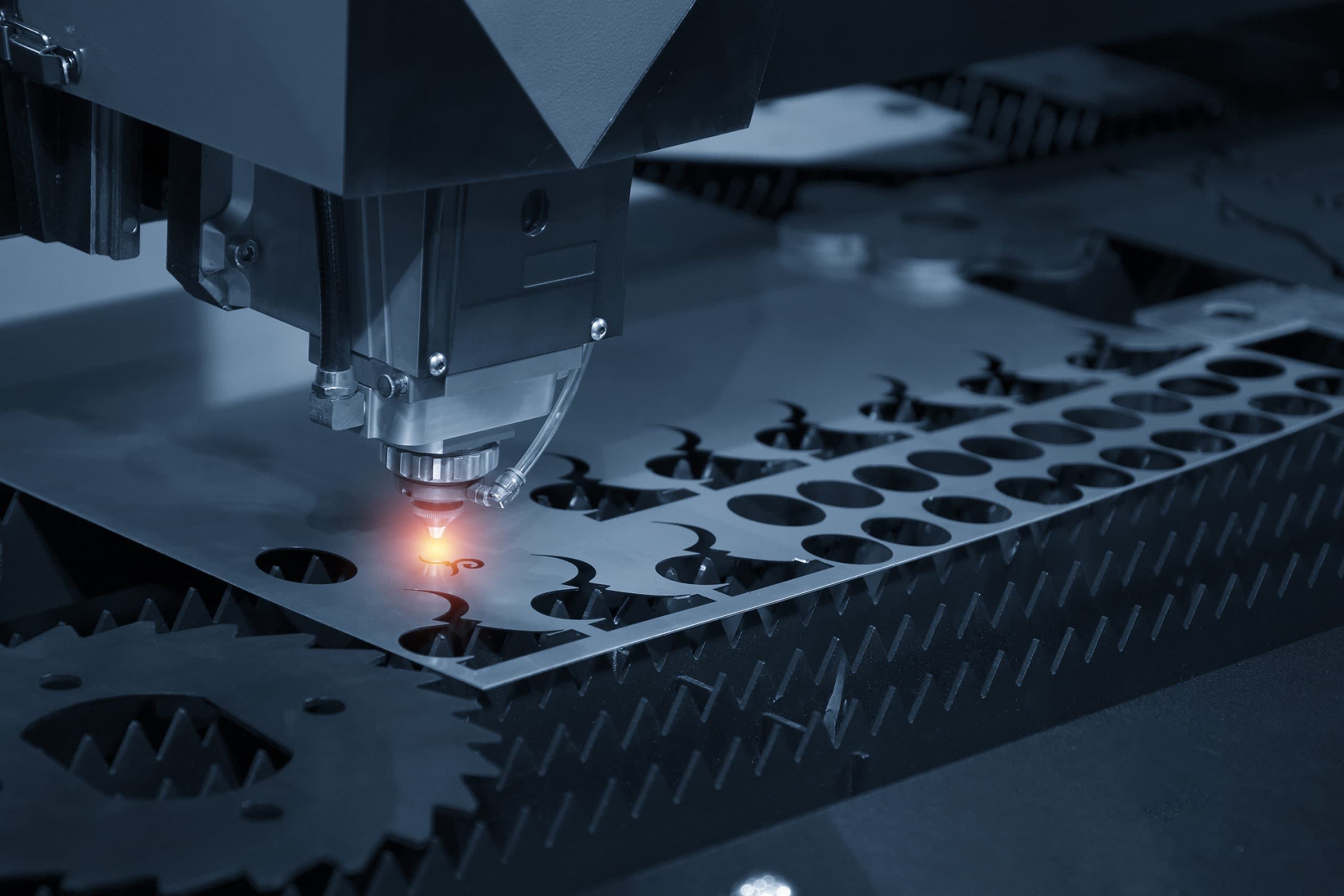

- Laser cutting: Using cutting-edge laser cutting technology like our Amada laser, we achieve components with tight tolerances and little to no need for further machining. Our Amada laser can cut steel up to 3/4″ thick, and we utilize modern software like SolidWorks to ensure accurate dimensions and design output. For sophisticated, close-tolerance cuts and detailed patterns, laser cutting can handle a wide range of materials and thicknesses.

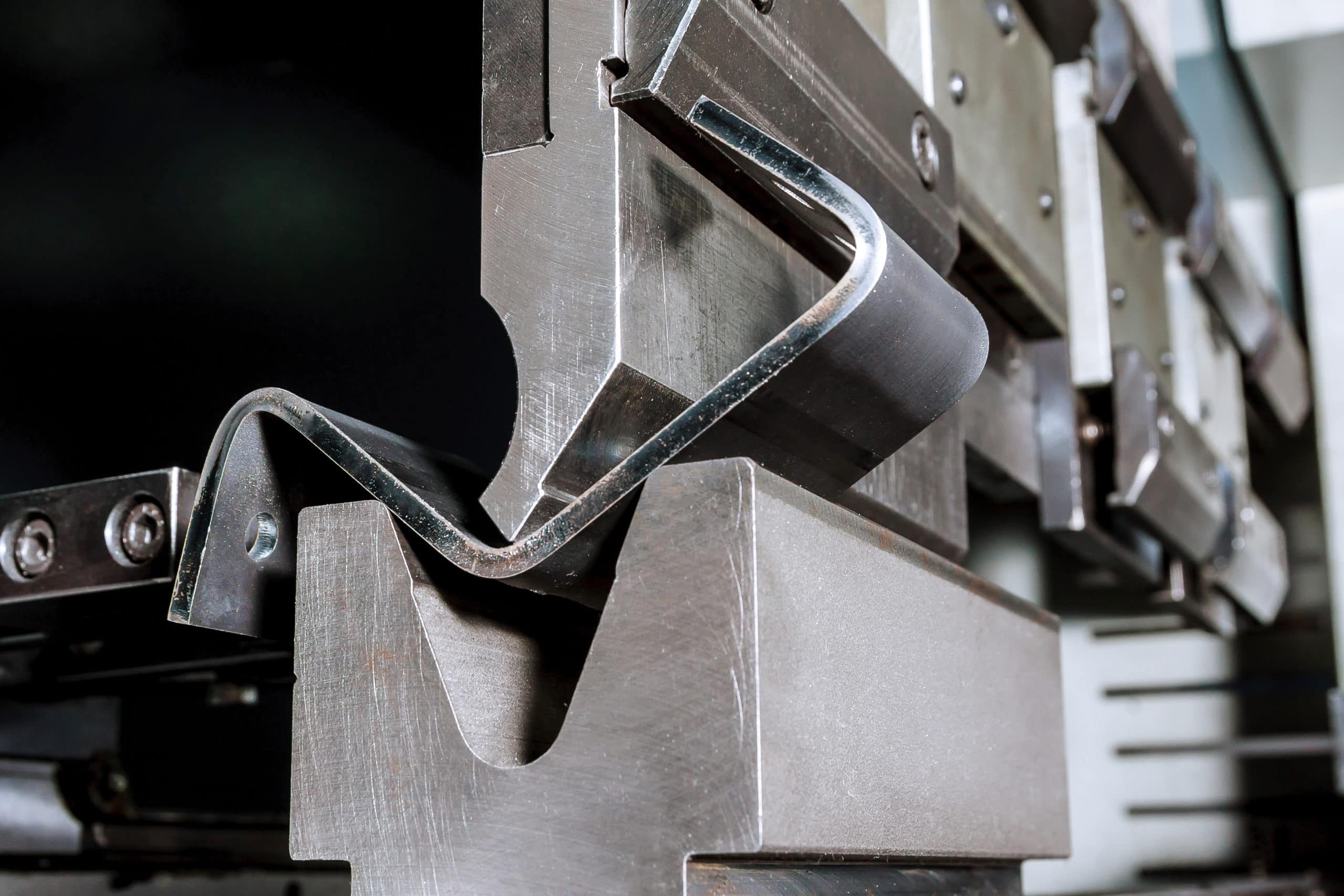

- Fabrication: With our extensive metal fabrication capabilities, we eliminate the need to seek out additional vendors to complete your project. Our fabricators are skilled in forming, bending, polishing, rolling, stamping, grinding, and many other fabrication techniques and we perform them all in-house. These value-added services save you time and money, and with our commitment to customer satisfaction, we guarantee you will be satisfied with the final product.

Industries Served

Shoemaker is proud to serve a wide variety of industries and companies. Some of the industries we serve most frequently include:

- Aerospace: Aerospace applications require components to meet rigorous industry standards that can be difficult to achieve for some vendors. Shoemaker can not only meet these standards using our extensive range of fabrication, machining, and welding capabilities, but we can also deliver them in a timely fashion, and at precise tolerances.

- Defense Work: We utilize our state-of-the-art CNC technology to provide high-precision components for defense applications. Accuracy and precision are of the utmost importance in defense work due to the mission-critical nature of these applications. Our machining technology and finishing techniques allow us to produce reliable parts for weaponry, machinery, and other defense equipment.

- Marine: Using our advanced surface finishing techniques, we can expertly produce marine equipment that can withstand extended exposure to corrosive marine environments.

- Commercial: From general industrial manufacturing to packaging to government applications, the commercial sector requires a wide range of metal fabricated parts to operate smoothly. We have the skill and expertise to create custom metal products for the commercial sector.

Trust Shoemaker for your machining, metal fabrication, and welding needs!

Since the founding of the family’s company in 1958, Shoemaker is proud to serve the community by providing services like machining, welding, fabrication, and laser cutting. As an AS9100D-registered manufacturer and ITAR-compliant company, Shoemaker strives to attract and retain clients through excellent service and dependability. It doesn’t matter if you need a small piece fabricated or have a large welding job that needs to be done on time, Shoemaker MFG Solutions INC. is here to help. Contact us today to get a quote for your machining needs or speak with an expert to get your design started!

About Us

Shoemaker MFG Solutions, Inc. was established in 1958 by Harry Moyer Shoemaker. The original name was Harry M. Shoemaker Welding. Harry started the business, where it still operates today, located on Leidy Road in Souderton.

ISO 9001

Business Bureau®

Welding

Laser Cutting

Photo Gallery

View All Photos