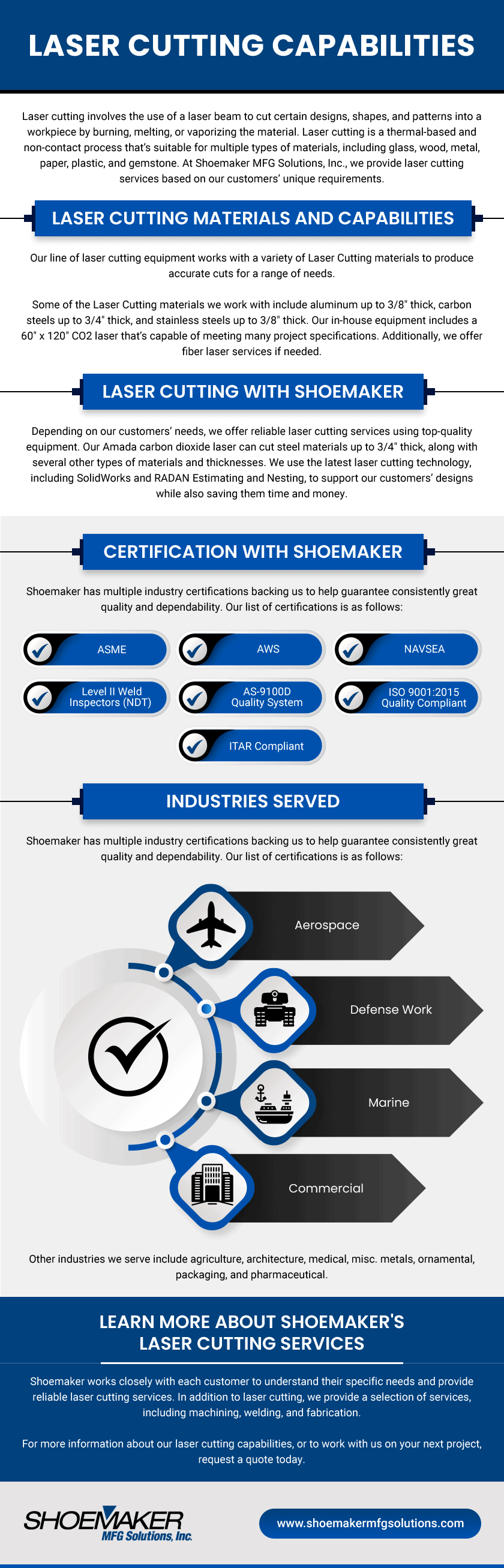

Laser cutting involves the use of a laser beam to cut certain designs, shapes, and patterns into a workpiece by burning, melting, or vaporizing the material. Co2 Laser cutting is a thermal-based and non-contact process that’s suitable for multiple types of materials, including glass, wood, metal. At Shoemaker MFG Solutions, Inc., we provide custom laser cutting and custom metal laser cutting services based on our customers’ unique requirements.

Laser Cutting Materials and Capabilities

Our line of laser cutting equipment works with a variety of laser cutting materials to produce accurate cuts for a range of needs.

Some of the laser cutting materials we work with include aluminum up to 3/8″ thick, carbon steels up to 3/4″ thick, and stainless steels up to 3/8″ thick. Our in-house equipment includes a 60″ x 120″ carbon dioxide laser cutting system that’s capable of meeting many project specifications. Additionally, we offer fiber laser services if needed.

Laser Cutting with Shoemaker

Depending on our customers’ needs, we offer reliable laser cutting services using top-quality equipment. Our Amada carbon dioxide laser can cut steel materials up to 3/4″ thick, along with several other types of materials and thicknesses. We use the latest laser cutting technology, including SolidWorks and RADAN Estimating and Nesting, to support our customers’ designs while also saving them time and money.

Certification with Shoemaker

- ASME — The American Society of Mechanical Engineers (ASME) certification indicates that a company is devoted to a combination of safety and quality with every product and service.

- AWS — Our team has received certification from the American Welding Society.

- NAVSEA — For our customers in the U.S. Navy, our services come with NAVSEA certification.

- Level II Weld Inspectors (NDT) — Our Level 2 welding inspectors have a minimum of two years of experience as Level 1 welding inspectors who perform under close supervision by certified personnel.

- AS-9100D quality system — Our AS-9100D certification enables us to perform services for customers in the aerospace industry.

- ISO 9001:2015 quality compliant — Our ISO 9001:2015 certification shows that we offer consistently high quality across our products and services that meet the necessary regulatory and statutory requirements.

- ITAR Compliant — Compliant with International Traffic in Arms Regulations.

- JCP Agreement — Approved Military Critical Technical Data Agreement, DD form 2345.

- CMMC Level 1

Industries Served

Shoemaker serves customers in multiple industries, including:

- Aerospace. The aerospace industry has strict requirements in place for quality and precision that the experts at Shoemaker can meet. Our customers in this sector include OEMs and suppliers in need of laser cutting and other fabrication services.

- Defense Work. Military and defense equipment must be reliable and hold up in many harsh environments. There is no room for error in this industry, so parts must be machined with the utmost precision.

- Marine. Parts used in marine applications need sufficient corrosion resistance in seawater and other harsh conditions. Our laser cutting services produce reliable parts for use in these applications.

- Commercial. Many commercial businesses need aluminum laser cutting and stainless steel laser cutting services to help fabricate high-quality components and parts, which we offer to customers in this industry.

Other industries we serve include agriculture, architecture, medical, misc. metals, ornamental, packaging, and pharmaceutical.

Learn More About Shoemaker’s Laser Cutting Services

Shoemaker works closely with each customer to understand their specific needs and provide reliable laser cutting services. In addition to laser cutting, we provide a selection of services, including machining, welding, and fabrication.

For more information about our laser cutting capabilities, or to work with us on your next project, request a quote today.