At Shoemaker MFG Solutions, we work with customers across numerous industries, including aerospace, agriculture, architecture, marine, military, medical, packaging, pharmaceutical, and more. We serve a diverse customer base with a range of manufacturing capabilities, such as fabrication, welding, machining, and laser cutting.

Fabrication

Metal fabrication is a broad term encompassing a variety of processes used to turn sheet metal stock into useable goods or parts. Metal fabrication processes typically lend themselves well to mass production and large-volume custom production runs.

At Shoemaker, we have extensive experience in a range of metal fabrication processes, including (but not limited to):

- Bending

- Folding

- Forming

- Polishing

- Punching

- Sandblasting

- Waterjet cutting

Welding

At its simplest, welding refers to the process of melting and fusing two separate pieces of metal together. Welding comes in a variety of forms, incorporating various combinations of heat, pressure, filler materials, and gas to form a strong and reliable joint between two workpieces. Determining the most appropriate welding process depends on the desired joint type, workpiece material, and other considerations.

Shoemaker has an on-site welding unit that allows us to shorten production timelines by conducting complex welding operations in-house. Our certified welders use several welding methods in our facility, including:

- MIG welding

- TIG welding

- Stick welding

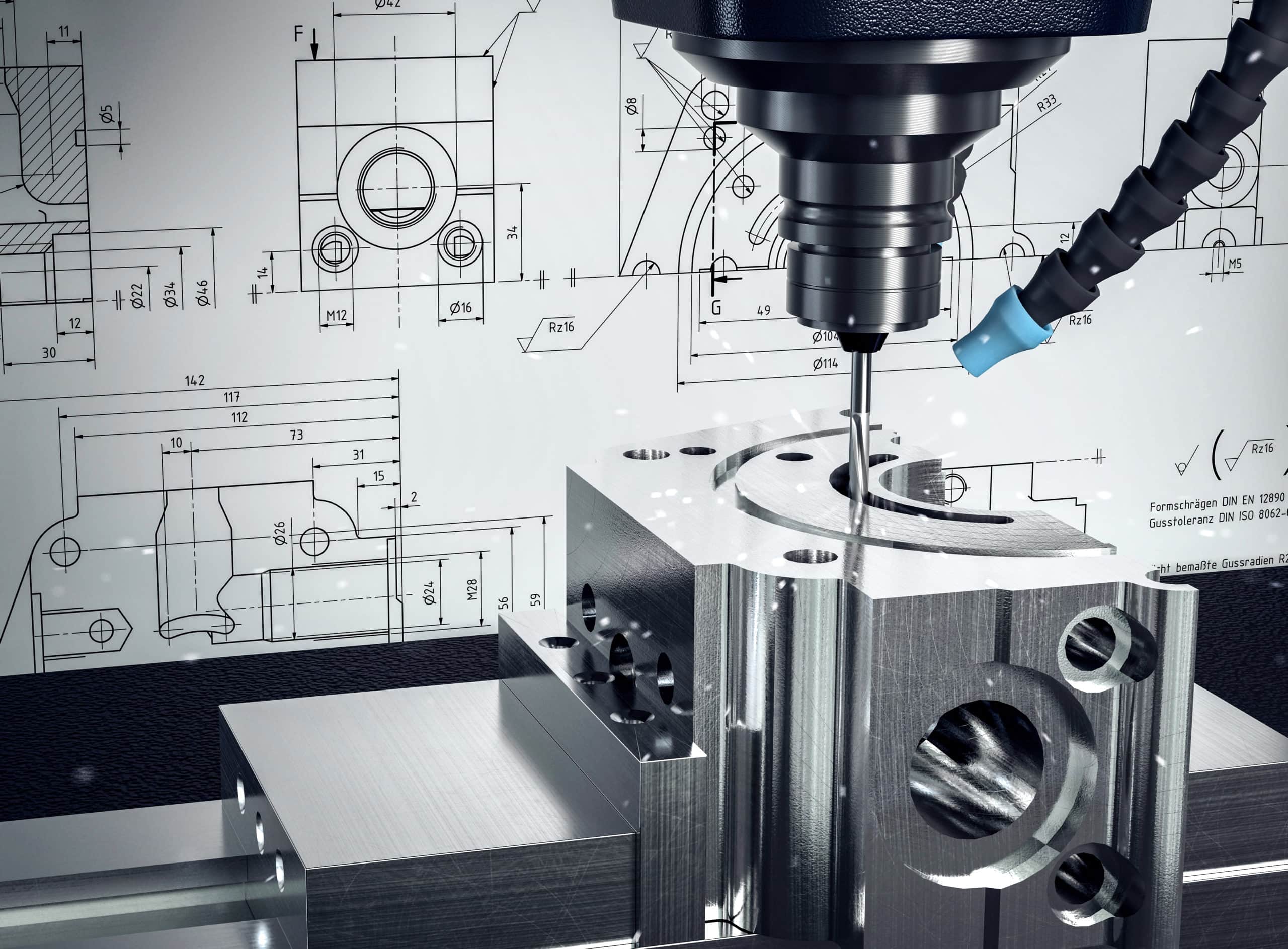

Machining

Machining is another broad term that encompasses a broad range of manufacturing processes used to remove material from a workpiece and shape it in accordance with design specifications. Metal components often require some sort of machining during the production process, though machining can also be used on plastic, rubber, paper, and other materials in certain situations.

At Shoemaker, we offer computer numerical control (CNC) automated machining, 3D dynamic machining, thread milling, and more using our extensive portfolio of machine tools:

- Band Saw Horizontal

- Band Saw Vertical

- CNC Turning Center

- Hone

- Manual Mills

- Manual Lathes

- Press

- Surface Grinder

- 4th and 5th Axis

Our skilled machining team works with the Mastercam and SolidWorks software suites to view computer-aided design (CAD) files and convert them into readable instructions for CNC machinery.

Laser Cutting

The laser cutting process uses a highly focused beam of light to burn through material, resulting in highly precise cuts. The cut edges often have a relatively accurate and smooth finish and require little secondary processing. Laser cutting can be used for simple trimming or making highly complex, close-tolerance cuts in accordance with detailed designs.

At Shoemaker, we use an Amada Laser with the ability to cut steel up to ¾” thick, and our laser cutting equipment can handle a variety of other materials and thicknesses as well. We rely on SolidWorks and other technology to view and unfold CAD files, helping us to streamline production times and cut costs.

About Shoemaker MFG Solutions, Inc.

Our team at Shoemaker MFG Solutions strives to acquire and retain customers through our commitment to superior and dependable service. We produce completed assemblies or individual components tailored exactly to the needs of the customer and only deliver services and products that meet the highest quality standards.

To see how our fabrication, welding, machining, and laser cutting capabilities can support your project, please contact us today.