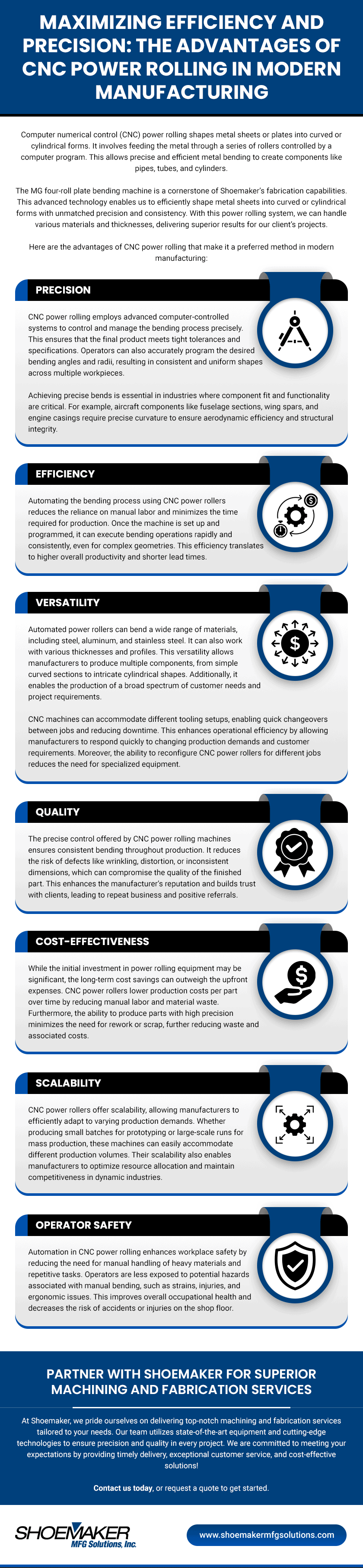

Maximizing Efficiency and Precision: The Advantages of CNC Power Rolling in Modern Manufacturing

Computer numerical control (CNC) power rolling shapes metal sheets or plates into curved or cylindrical forms. It involves feeding the metal through a series of rollers controlled by a computer program. This allows precise and efficient metal bending to create components like pipes, tubes, and cylinders.

The MG four-roll plate bending machine is a cornerstone of Shoemaker’s fabrication capabilities. This advanced technology enables us to efficiently shape metal sheets into curved or cylindrical forms with unmatched precision and consistency. With this power rolling system, we can handle various materials and thicknesses, delivering superior results for our client’s projects.

Here are the advantages of CNC power rolling that make it a preferred method in modern manufacturing:

1. Precision

CNC power rolling employs advanced computer-controlled systems to control and manage the bending process precisely. This ensures that the final product meets tight tolerances and specifications. Operators can also accurately program the desired bending angles and radii, resulting in consistent and uniform shapes across multiple workpieces.

Achieving precise bends is essential in industries where component fit and functionality are critical. For example, aircraft components like fuselage sections, wing spars, and engine casings require precise curvature to ensure aerodynamic efficiency and structural integrity.

2. Efficiency

Automating the bending process using CNC power rollers reduces the reliance on manual labor and minimizes the time required for production. Once the machine is set up and programmed, it can execute bending operations rapidly and consistently, even for complex geometries. This efficiency translates to higher overall productivity and shorter lead times.

3. Versatility

Automated power rollers can bend a wide range of materials, including steel, aluminum, and stainless steel. It can also work with various thicknesses and profiles. This versatility allows manufacturers to produce multiple components, from simple curved sections to intricate cylindrical shapes. Additionally, it enables the production of a broad spectrum of customer needs and project requirements.

CNC machines can accommodate different tooling setups, enabling quick changeovers between jobs and reducing downtime. This enhances operational efficiency by allowing manufacturers to respond quickly to changing production demands and customer requirements. Moreover, the ability to reconfigure CNC power rollers for different jobs reduces the need for specialized equipment.

4. Quality

The precise control offered by CNC power rolling machines ensures consistent bending throughout production. It reduces the risk of defects like wrinkling, distortion, or inconsistent dimensions, which can compromise the quality of the finished part. This enhances the manufacturer’s reputation and builds trust with clients, leading to repeat business and positive referrals.

5. Cost-Effectiveness

While the initial investment in power rolling equipment may be significant, the long-term cost savings can outweigh the upfront expenses. CNC power rollers lower production costs per part over time by reducing manual labor and material waste. Furthermore, the ability to produce parts with high precision minimizes the need for rework or scrap, further reducing waste and associated costs.

6. Scalability

CNC power rollers offer scalability, allowing manufacturers to efficiently adapt to varying production demands. Whether producing small batches for prototyping or large-scale runs for mass production, these machines can easily accommodate different production volumes. Their scalability also enables manufacturers to optimize resource allocation and maintain competitiveness in dynamic industries.

7. Operator Safety

Automation in CNC power rolling enhances workplace safety by reducing the need for manual handling of heavy materials and repetitive tasks. Operators are less exposed to potential hazards associated with manual bending, such as strains, injuries, and ergonomic issues. This improves overall occupational health and decreases the risk of accidents or injuries on the shop floor.

Partner With Shoemaker for Superior Machining and Fabrication Services

At Shoemaker, we pride ourselves on delivering top-notch machining and fabrication services tailored to your needs. Our team utilizes state-of-the-art equipment and cutting-edge technologies to ensure precision and quality in every project. We are committed to meeting your expectations by providing timely delivery, exceptional customer service, and cost-effective solutions!

Contact us today, or request a quote to get started.