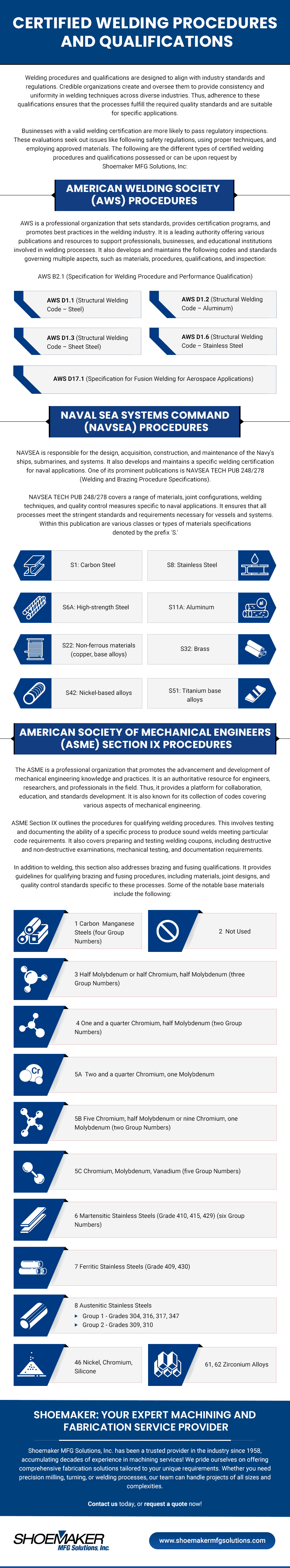

Welding procedures and qualifications are designed to align with industry standards and regulations. Credible organizations create and oversee them to provide consistency and uniformity in welding techniques across diverse industries. Thus, adherence to these qualifications ensures that the processes fulfill the required quality standards and are suitable for specific applications.

Businesses with a valid welding certification are more likely to pass regulatory inspections. These evaluations seek out issues like following safety regulations, using proper techniques, and employing approved materials. The following are the different types of certified welding procedures and qualifications possessed or can be upon request by Shoemaker MFG Solutions, Inc:

American Welding Society (AWS) Procedures

AWS is a professional organization that sets standards, provides certification programs, and promotes best practices in the welding industry. It is a leading authority offering various publications and resources to support professionals, businesses, and educational institutions involved in welding processes. It also develops and maintains the following codes and standards governing multiple aspects, such as materials, procedures, qualifications, and inspection:

AWS B2.1 (Specification for Welding Procedure and Performance Qualification)

- AWS D1.1 (Structural Welding Code – Steel)

- AWS D1.2 (Structural Welding Code – Aluminum)

- AWS D1.3 (Structural Welding Code – Sheet Steel)

- AWS D1.6 (Structural Welding Code – Stainless Steel

- AWS D17.1 (Specification for Fusion Welding for Aerospace Applications)

Naval Sea Systems Command (NAVSEA) Procedures

NAVSEA is responsible for the design, acquisition, construction, and maintenance of the Navy’s ships, submarines, and systems. It also develops and maintains a specific welding certification for naval applications. One of its prominent publications is NAVSEA TECH PUB 248/278 (Welding and Brazing Procedure Specifications).

NAVSEA TECH PUB 248/278 covers a range of materials, joint configurations, welding techniques, and quality control measures specific to naval applications. It ensures that all processes meet the stringent standards and requirements necessary for vessels and systems. Within this publication are various classes or types of materials specifications denoted by the prefix ‘S.’

- S1: Carbon steel

- S8: Stainless steel

- S6A: High-Alloysteel

- S22: Aluminum

- S31: Non-ferrous materials (copper, base alloys)

- S32: Brass

- S42: Nickel-based alloys

- S51: Titanium base alloys

American Society of Mechanical Engineers (ASME) Section IX Procedures

The ASME is a professional organization that promotes the advancement and development of mechanical engineering knowledge and practices. It is an authoritative resource for engineers, researchers, and professionals in the field. Thus, it provides a platform for collaboration, education, and standards development. It is also known for its collection of codes covering various aspects of mechanical engineering.

ASME Section IX outlines the procedures for qualifying welding procedures. This involves testing and documenting the ability of a specific process to produce sound welds meeting particular code requirements. It also covers preparing and testing welding coupons, including destructive and non-destructive examinations, mechanical testing, and documentation requirements.

In addition to welding, this section also addresses brazing and fusing qualifications. It provides guidelines for qualifying brazing and fusing procedures, including materials, joint designs, and quality control standards specific to these processes. Some of the notable base materials include the following:

- 1 Carbon Manganese Steels (four Group Numbers)

- 2 Not Used

- 3 Half Molybdenum or half Chromium, half Molybdenum (three Group Numbers)

- 4 One and a quarter Chromium, half Molybdenum (two Group Numbers)

- 5A Two and a quarter Chromium, one Molybdenum

- 5B Five Chromium, half Molybdenum or nine Chromium, one Molybdenum (two Group Numbers)

- 5C Chromium, Molybdenum, Vanadium (five Group Numbers)

- 6 Martensitic Stainless Steels (Grade 410, 415, 429) (six Group Numbers)

- 7 Ferritic Stainless Steels (Grade 409, 430)

- 8 Austenitic Stainless Steels

- Group 1 – Grades 304, 316, 317, 347

- Group 2 – Grades 309, 310

- 46 Nickel, Chromium, Silicone

- 61, 62 Zirconium Alloys

Shoemaker: Your Expert Machining and Fabrication Service Provider

Shoemaker MFG Solutions, Inc. has been a trusted provider in the industry since 1958, accumulating decades of experience in machining services! We pride ourselves on offering comprehensive fabrication solutions tailored to your unique requirements. Whether you need precision milling, turning, or welding processes, our team can handle projects of all sizes and complexities.

Contact us today, or request a quote now!