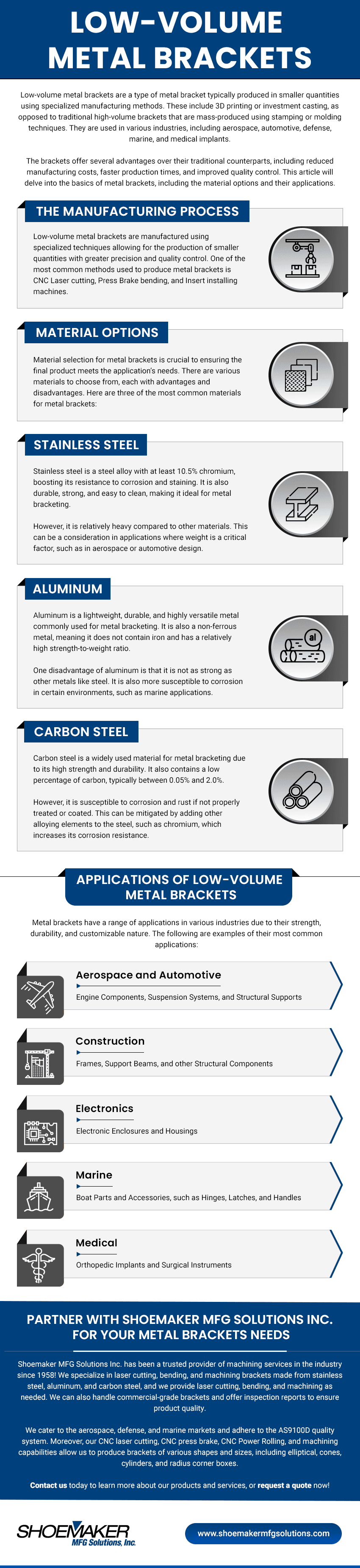

Low-volume metal brackets are a type of metal bracket typically produced in smaller quantities using specialized manufacturing methods. These include 3D printing or investment casting, as opposed to traditional high-volume brackets that are mass-produced using stamping or molding techniques. They are used in various industries, including aerospace, automotive, defense, marine, and medical implants.

The brackets offer several advantages over their traditional counterparts, including reduced manufacturing costs, faster production times, and improved quality control. This article will delve into the basics of metal brackets, including the material options and their applications.

The Manufacturing Process

Low-volume metal brackets are manufactured using specialized techniques allowing for the production of smaller quantities with greater precision and quality control. One of the most common methods used to produce metal brackets is CNC Laser cutting, Press Brake bending, and Insert installing machines.

Material Options

Material selection for metal brackets is crucial to ensuring the final product meets the application’s needs. There are various materials to choose from, each with advantages and disadvantages. Here are three of the most common materials for metal brackets:

Stainless Steel

Stainless steel is a steel alloy with at least 10.5% chromium, boosting its resistance to corrosion and staining. It is also durable, strong, and easy to clean, making it ideal for metal bracketing.

However, it is relatively heavy compared to other materials. This can be a consideration in applications where weight is a critical factor, such as in aerospace or automotive design.

Aluminum

Aluminum is a lightweight, durable, and highly versatile metal commonly used for metal bracketing. It is also a non-ferrous metal, meaning it does not contain iron and has a relatively high strength-to-weight ratio.

One disadvantage of aluminum is that it is not as strong as other metals like steel. It is also more susceptible to corrosion in certain environments, such as marine applications.

Carbon Steel

Carbon steel is a widely used material for metal bracketing due to its high strength and durability. It also contains a low percentage of carbon, typically between 0.05% and 2.0%.

However, it is susceptible to corrosion and rust if not properly treated or coated. This can be mitigated by adding other alloying elements to the steel, such as chromium, which increases its corrosion resistance.

Applications of Low-Volume Metal Brackets

Metal brackets have a range of applications in various industries due to their strength, durability, and customizable nature. The following are examples of their most common applications:

- Aerospace and automotive: engine components, suspension systems, and structural supports

- Construction: frames, support beams, and other structural components

- Electronics: electronic enclosures and housings

- Marine: boat parts and accessories, such as hinges, latches, and handles

- Medical: orthopedic implants and surgical instruments

Partner With Shoemaker MFG Solutions Inc. for Your Metal Brackets Needs

Shoemaker MFG Solutions Inc. has been a trusted provider of machining services in the industry since 1958! We specialize in laser cutting, bending, and machining brackets made from stainless steel, aluminum, and carbon steel, and we provide laser cutting, bending, and machining as needed. We can also handle commercial-grade brackets and offer inspection reports to ensure product quality.

We cater to the aerospace, defense, and marine markets and adhere to the AS9100D quality system. Moreover, our CNC laser cutting, CNC press brake, CNC Power Rolling, and machining capabilities allow us to produce brackets of various shapes and sizes, including elliptical, cones, cylinders, and radius corner boxes.

Contact us today to learn more about our products and services, or request a quote now!